What Does FIFO stand for?

What does FIFO stand for? FIFO stands for “First In, First Out.” It’s a method of inventory valuation or a system for managing and accounting for inventory that assumes that

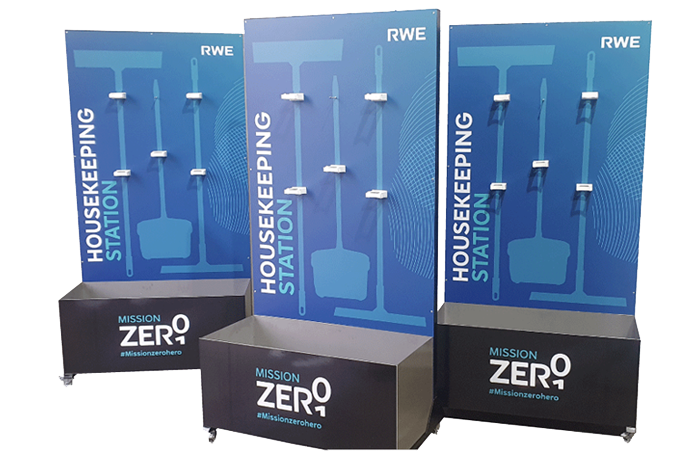

Shadow Boards

Lean 5S Products UK provides solutions to every manufacturing and service sector to improve 5S and lean management initiatives with our customised Visual management, Shadow Boards and Management Boards.

We design and produce to a high standard fully bespoke Tool Shadow Boards, Foam Shadow Boards, Cleaning Stations, and Informational & Organisation Boards.

We offer unlimited design revisions incorporating specific shadow requirements, text, logos, colours and branding so you get a bespoke Shadow/Production Board that makes your workplace more efficient and profitable. We can also supply the cleaning and other tools required.

Lean 5S Products UK responds in a quick and friendly manner making us your turnkey 5S solution.

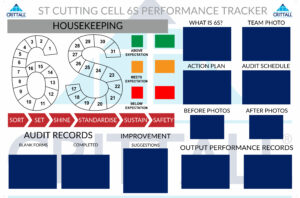

Developed by the Management of Toyota in Japan, the 5s system organizes the workplace based on the 5 “pillars”

Custom means exactly that. Choose colors, sizes, layout, tool hardware, material substrate AND choose between Wall mounted, free standing or mobile carts. We also supply colour coded cleaning tools too.

Get a free quote today

The most efficient organisation of tools and equipment contributes to less workplace accidents and creates a higher level of employee morale and pride. Our Lean 5S Products UK Shadow Boards act as visual aids and encourage area cleanliness and workplace safety.

What does FIFO stand for? FIFO stands for “First In, First Out.” It’s a method of inventory valuation or a system for managing and accounting for inventory that assumes that

In the world of manufacturing, efficiency is king. Every wasted minute, every unnecessary movement, and every miscommunication can result in lost productivity and revenue. That’s why implementing effective visual controls

Introducing the Lectern Tool Shadow Board, your ultimate solution for streamlined tool organisation. Say goodbye to the frustration of misplaced tools and hello to efficiency and productivity. With its intuitive