Visual Controls: What Are the Benefits for UK Manufacturing?

In the world of manufacturing, efficiency is king. Every wasted minute, every unnecessary movement, and every miscommunication can result in lost productivity and revenue. That’s why implementing effective visual controls is essential for streamlining operations and maximizing efficiency. But what exactly are visual controls, and what benefits do they offer for manufacturing in the UK?

Understanding Visual Controls

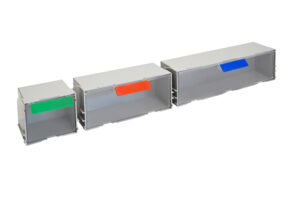

Visual controls are tools and techniques used to convey information quickly and clearly through visual cues. These cues can take various forms, such as signs, labels, color-coding, charts, graphs, and more. The goal is to make important information easily accessible and understandable at a glance, without the need for extensive interpretation or explanation.

Benefits for UK Manufacturing

1. Enhanced Communication

In a manufacturing environment, effective communication is paramount. Visual controls provide a universal language that transcends linguistic barriers, making it easier for diverse teams to understand and follow procedures. Whether it’s indicating safety hazards, displaying production targets, or highlighting quality standards, visual cues ensure that crucial information is communicated clearly and consistently across the organization.

2. Improved Efficiency

Time is money, especially in the fast-paced world of manufacturing. Visual controls help reduce wasted time by providing instant feedback and guidance to workers. For example, using visual cues to mark optimal inventory levels can prevent overstocking or stockouts, minimizing downtime and maximizing production efficiency. Similarly, visual indicators on machinery can quickly alert operators to any issues or maintenance requirements, reducing the risk of costly breakdowns and delays.

3. Error Reduction

Human error is inevitable, but visual controls can help minimize its impact. By providing visual prompts and instructions, workers are less likely to make mistakes or overlook important details. For instance, using color-coded labels to differentiate between similar components can prevent mix-ups and assembly errors. Likewise, visual work instructions can guide operators through complex processes step by step, reducing the risk of quality defects and rework.

4. Increased Safety

Safety is non-negotiable in any manufacturing setting. Visual controls play a crucial role in promoting a safe work environment by highlighting potential hazards and reinforcing best practices. Whether it’s marking designated walkways, indicating emergency exits, or outlining proper equipment usage, visual cues remind workers to prioritize safety at all times. This not only protects employees from harm but also reduces the likelihood of accidents and regulatory non-compliance.

5. Continuous Improvement

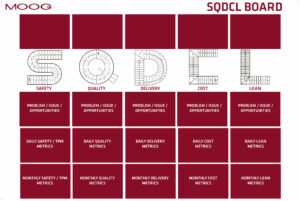

In today’s competitive market, manufacturers must continuously strive for improvement. Visual controls facilitate this process by making it easier to monitor performance, identify inefficiencies, and implement corrective actions. By visually tracking key performance indicators (KPIs) such as production output, cycle times, and defect rates, organizations can quickly spot trends and areas for improvement. This proactive approach to problem-solving fosters a culture of continuous improvement, driving greater efficiency and competitiveness in the long run.

Conclusion

In conclusion, visual controls are indispensable tools for enhancing communication, improving efficiency, reducing errors, ensuring safety, and driving continuous improvement in UK manufacturing. By leveraging visual cues to convey information quickly and clearly, organizations can streamline operations, maximize productivity, and stay ahead of the competition in today’s fast-paced market. As technology continues to evolve, manufacturers must embrace visual controls as a fundamental aspect of their operational strategy to thrive in an increasingly competitive global landscape.

Of Course we can help! www.lean5sproducts.co.uk